Environmental monitoring has always been an important program for food plants, especially those that handle microbiologically sensitive foods. With the recent regulatory focus on identifying and controlling food hazards, more and more food facilities, including those that handle products that have not historically been associated with microbiological hazards, are establishing and improving their environmental monitoring programs.

Unfortunately, budget restrictions leave many plants without a food microbiologist on staff, placing the environmental monitoring responsibilities on the quality assurance manager or plant manager. Such technical tasks make an already complicated job even more difficult for those who do not have a science background or prior experience in environmental monitoring. This general guidance will help food plants establish an environmental monitoring program that covers the necessary bases.

What is environmental monitoring?

Environmental monitoring is an evaluation of the effectiveness of the microbial controls (pathogens and spoilage organisms) to prevent contamination of food products. It is not only a validation of the sanitation program, but an evaluation of multiple programs, including but not limited to sanitary design, personnel practices, operational methods, and supplier control.

Where should sampling take place?

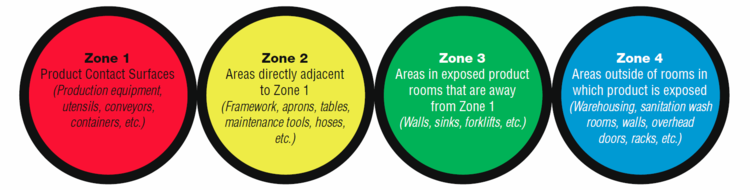

The best practice is to use the four-zone system when determining what areas to take samples from. As shown in the four color graphic, the four-zone system begins at the product-contact surfaces, and extends to areas outside of rooms in which product is exposed. The least amount or no testing should be done in Zone 1. If pathogens are found in Zone 1, it is likely a recall situation and it is too late.

Sampling should focus on high-risk areas, such as:

- Zone 2, which has greater access to the product.

- Wet areas, which encourage growth.

- Warm areas, which encourage growth.

When should sampling take place?

A common misconception is that environmental monitoring should take place immediately after sanitation. Remember, these samples are not designed to validate the effectiveness of cleaning and sanitizing methods, but are more focused on validating cleaning and sanitizing frequency and all the programs of the Good Manufacturing Practices (21 CFR).

What organisms should we test?

There are three categories of organisms that can be included in the environmental testing: pathogens, spoilage organisms, and indicator organisms.

Pathogens

It is important to test for the pathogens of relevance to your type of operation. The test for pathogens is simply present or absent; enumeration is not necessary.

- Listeria - Listeria monocytogenes is the only currently known pathogenic Listeria species, however, it is recommended to test only for the Listeria genus and assume it is Listeria monocytogenes. Listeria is commonly associated with raw vegetables, cheese, and ice and is commonly found in wet or cool environments and in drains.

- Salmonella - All species of Salmonella are pathogenic. Salmonella is commonly associated with eggs, poultry, flour, milk, vegetables, spices, and nuts. It is commonly found in environments with high and low moisture, in air intakes, and in areas that have pest activity.

- Escherichia coli (E. coli). - Not all species of E.coli are pathogenic. Oserovars, such as E.coli O157:H7, are pathogenic. You can test for coliforms as an indicator of E.coli. This pathogen

is commonly associated with meat, poultry, eggs, cheese, fruits, and vegetables. It is often found in soil, and is associated with contaminated water and areas where fecal-contamination may occur (personnel). - Campylobacter - Not all species of Campylobacter are pathogenic, but product is exposed. The least amount or no testing should be done in Zone 1. If pathogens are found in Zone 1, it is likely a recall situation and it is too late.

- Staphylococcus aureus - Not all Staphylococcus are pathogenic. This pathogen causes intoxication, not infection. It is commonly associated with meat, seafood, eggs, and bakery products and is linked to food handlers.

- Bacillus cereus - Bacillus cereus causes intoxication and infection. It forms spores and can be resistant to high temperatures. This pathogen is commonly associated with wheat flour, corn flour, vegetables, meat, milk, rice, spices, soy and whey proteins, and yeast. The environments most closely associated with Bacillus cereus include mills, bakeries, dusty areas, post-kill step, and air vents.

Spoilage Organisms

Yeast and mold are the most concerning spoilage organisms that food facilities should include in their environmental monitoring programs. The most common molds are Aspergillus, Fusarium, Penicillium, and Alternaria. Air and surface testing are both equally important in identifying the presence of these organisms.

Indicator Organisms

Indicator organisms are a basic monitoring tool used to measure the potential presence of hard-to-detect pathogenic organisms. They provide evidence of the presence or absence of a pathogenic organism that survives under similar physical, chemical, and nutrient conditions.

- Coliforms - Coliforms are only suggested for use if E. coli is a pathogen of concern. This indicator organism indicates the presence of fecal contamination.

- Enterobacteriacae - Enterobacteriacae is the most recommended indicator organisms. They are used to identify fecal contamination and post-heat processing contamination.

- Aerobic Plate Count (APC) - Aerobic plate count is often used due to low cost and quick results but there are many limitations. APC will not indicate Listeria, yeast, mold, or Camplylobacter.

An indicator organism is not necessarily a pathogen. Although some strains of E. coli are pathogenic, the reason coliforms and Enterobacteriacae are used is because they have proven to be indicative of recent fecal contamination. In addition, their behavior in the environment is assumed to be similar to actual pathogens of concern, and there is a relatively fast method of

analysis available.

How is a baseline established?

The Compendium of Methods for the Microbiological Evaluation of Foods provides some recommendations for establishing a monitoring baseline. However, there is a great variation in baselines depending on the product and process.

Use the following data sources to establish a baseline that fits the product and process at your facility:

- Historical results

- Clean-room qualification

- Sanitation studies

Generate trend reports based on the location, shift, room, and product(s) being run. It is advised that a year’s worth of data be analyzed to identify seasonal shifts. Avoid averaging results to set baselines as this can give either inappropriately high or inappropriately low levels.

Baselines are based on what is normally attainable. For example, a site may test <100 cfu for 10 of 12 months with two months with spikes. The 100 cfu would be set as the baseline. Baseline should be adjusted (lowered) as part of continuous improvement when previously set baselines

are always met. There should be a zero limit for pathogens.

What are other considerations?

Persons collecting samples must be knowledgeable about aseptic technique to ensure that they do not contaminate the samples.

“Hot spots” or elevated results need to be investigated to determine the root cause. Not only does the organism need to be eliminated with thorough cleaning and sanitation, but measures need to be taken to prevent it from being reintroduced.

As with any food plant program, documentation is a key component to ensure that the program is successfully operating.

Pingback from charmdev-websitetestlink.charm.com

https://charmdev-websitetestlink.charm.com/criticality-environmental-sampling/